Discover essential tips for maintaining equipment to ensure longevity and optimal performance. Learn how proper maintenance can save time and money.

Introduction: The Value of Equipment Maintenance

Maintaining equipment is not only about addressing issues as they arise but also ensuring longevity and optimal performance. Whether it's machinery, electronics, or tools, proper maintenance can save time and money while preventing unexpected breakdowns. Let's explore essential tips for effectively maintaining equipment in various settings.

Understanding Manufacturer Guidelines

One of the fundamental aspects of equipment maintenance is understanding and adhering to manufacturer guidelines. These guidelines often include recommended maintenance schedules, lubrication requirements, cleaning procedures, and more. Following these instructions meticulously can significantly prolong the lifespan of the equipment and help maintain its warranty coverage.

Regular Inspections and Cleaning

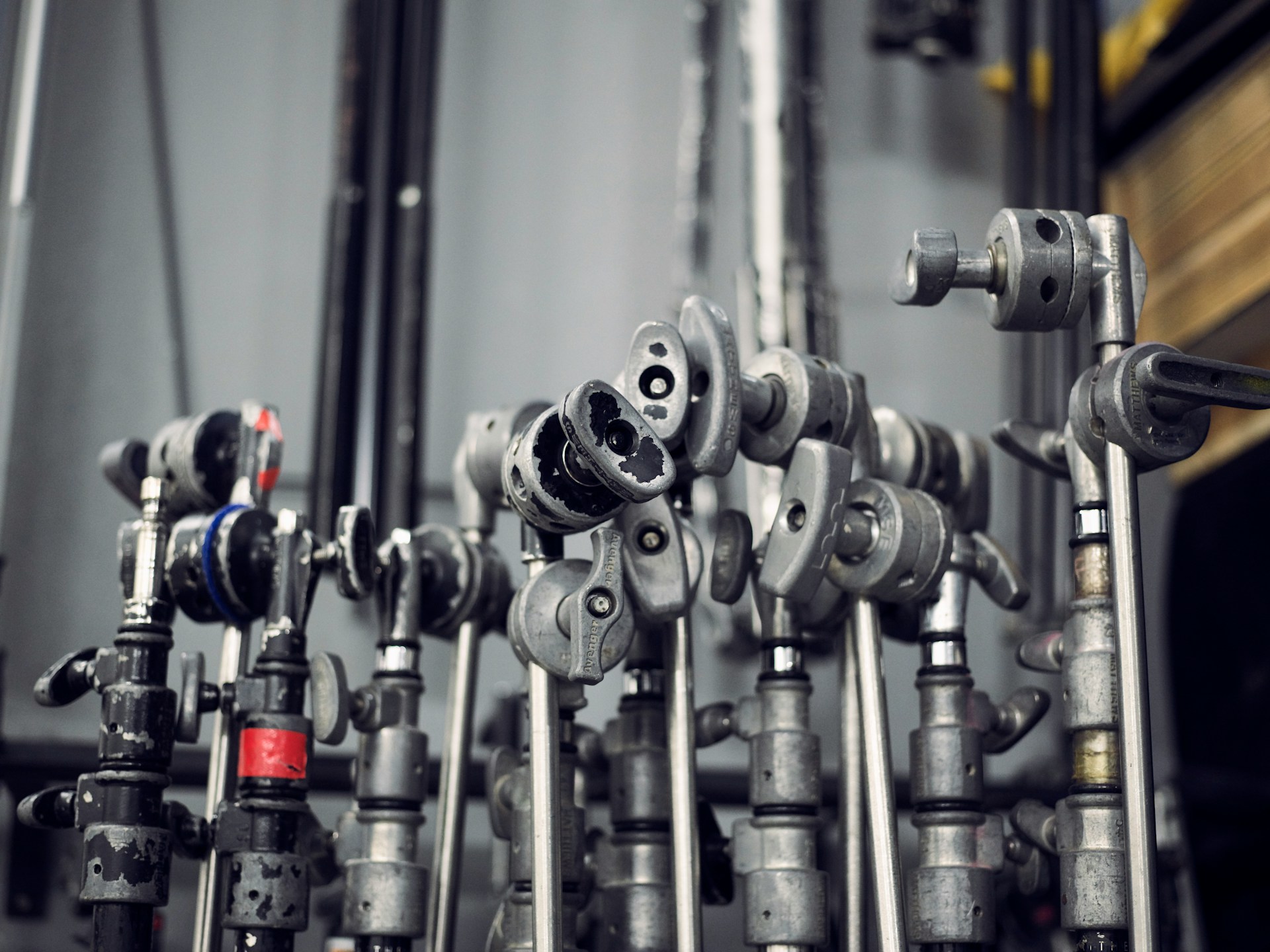

Regular inspections are vital for identifying early signs of wear and tear, as well as potential issues that may escalate if left unattended. Inspecting moving parts, electrical components, fluid levels, and overall structural integrity can preemptively address minor problems before they become major faults. Additionally, routine cleaning prevents dirt, debris, and corrosion from compromising the equipment's functionality.

Lubrication and Fluid Management

Proper lubrication of moving parts and efficient management of fluids are critical for the smooth operation of many types of equipment. Over time, lubricants degrade, leading to increased friction and wear. Regularly checking and replenishing lubricants, as well as monitoring fluid levels and quality, are integral to preventing premature equipment failure.

Calibration and Adjustment

Many types of equipment rely on precise calibration and adjustment for accurate performance. Whether it's measuring instruments, machining tools, or electronic devices, periodic recalibration ensures that the equipment continues to deliver reliable results. Regular adjustment of settings, alignments, and configurations also contributes to maintaining optimal functionality.

Component Replacement and Upgrades

As equipment ages, certain components may require replacement due to wear, fatigue, or technological obsolescence. Identifying components that are prone to failure and proactively replacing them can prevent costly disruptions. Furthermore, considering upgrades or retrofits for outdated components can enhance the performance and efficiency of the equipment.

Training and Personnel Involvement

In many settings, the individuals operating and maintaining the equipment play a crucial role in its longevity. Providing comprehensive training on proper usage, maintenance protocols, and early issue detection empowers personnel to actively contribute to equipment preservation. Encouraging a culture of ownership and responsibility can lead to more proactive maintenance practices.

Environmental Considerations

The environment in which equipment operates can significantly impact its longevity. Factors such as temperature, humidity, exposure to corrosive substances, and operational stressors should be taken into account when developing maintenance plans. Implementing protective measures and environmental controls can mitigate these factors and extend equipment lifespan.

Localized Maintenance: Electricians in Indianapolis, Indiana

For those based in Indianapolis, Indiana, leveraging local expertise is vital, particularly when it comes to the maintenance of electrical equipment. Licensed electricians in Indianapolis are well-versed in the unique challenges posed by the region's climatic conditions. They can provide targeted maintenance services that comply with local codes and standards.

Working with such professionals ensures not only the functionality and safety of electrical systems but also that maintenance procedures are up to date with the latest regional regulations. Their proximity allows for swift response times for inspections, emergency repairs, and routine upkeep, minimizing downtime and enhancing the overall longevity of the equipment.

Documentation and Record-Keeping

Maintaining detailed records of equipment maintenance activities, including inspections, repairs, replacements, and upgrades, is essential for tracking its history and performance. This documentation provides valuable insights into recurring issues, maintenance costs, and the overall effectiveness of the maintenance program, facilitating informed decision-making.

Conclusion

Efficient equipment maintenance is a proactive investment that yields long-term benefits, including extended lifespan, reduced downtime, and lower operational costs.

By following manufacturer guidelines, conducting regular inspections, managing lubrication and fluids, prioritizing calibration, involving personnel, and considering environmental factors, you can ensure that your equipment operates at its best for years to come. Remember, preventive maintenance today can prevent costly repairs tomorrow.